30m/min roof sheet roll forming machine hydraulic cutter

$20000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | TIANJIN XINGANG |

$20000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | TIANJIN XINGANG |

Model No.: YY-001

Brand: YY

Applicable Industries: Building Material Shops, Manufacturing Plant, Food Shop, Construction works

Showroom Location: None

Condition: New

Type: Tile Forming Machine

Tile Type: Glazed Steel

Use: Roof

Production Capacity: 10-20m/Min

Brand Name: YINGYEE

Dimension(L*W*H): 11000 x 1400 x 1400mm

Warranty: 1 Year

Key Selling Points: Easy To Operate

Rolling Thinckness: 0.3-1mm

Feeding Width: 1220mm

Machinery Test Report: Provided

Video Outgoing-inspection: Provided

Marketing Type: New Product 2020

Warranty Of Core Components: 1 Year

Core Components: Gear

After-sales Service Provided: Engineers Available To Service Machinery Overseas

Control System: PLC and touc screen

Thickness Of The Material: 0.3-1mm

Power: Hydraulic

Steel Automation: Automatic

After Warranty Service: Spare Parts

Applicable Industry: Machinery Repair Shops, Building Material Shops, Manufacturing Plant, Other

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Old And New: New

Machine Type: Tile Forming Machine

Productivity: 30 M/Min

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Automatic

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Place Of Origin: Hebei, China

Voltage: 380V/50HZ

Weight: 10 kg

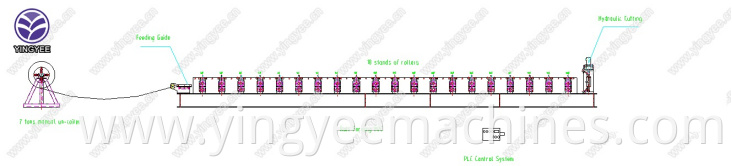

-machine components

One Purlin Forming machine can produce many sizes of purlin .

The line mainly consist of uncoiler , coil sheet guiding device ,flattening device ,roll forming system ,

punching equipment ,cutting equipment , hydraulic station ,PLC controlling system and support table .

Main technical parameters

| 5 ton Manual Decoiler | 1: Max width of raw Material :1250mm 2: Capacity: 5000kgs 3: Inner diameter of coil: 450-600mm |

| Roll forming machine | 1.Matching material:PPGI/GI/Aluminium 2.Material thickness:0.2-1mm 3.Power:7.5kw 4.Forming speed:30m/min 5.The width of the plates:according to the drawings 6.input leveling equipment:adjustable as photos. 7.Roll stations: about 22 rollers 8.Shaft Material and diameter:materialis45#steel 80mm, 9.Tolerance:10m±1.5mm 10.Way of drive:chain with the motor 11.Controlling system:PLC 12.Voltage,Frequency,Phase:depend on customer request 13.Material of forming rollers:45#steel heat treatment and chromed 14Materialofcutterblade:Cr12mouldsteelwith quenched treatmentHRC58-62 15. Side plate:steel plate with Chromed. |

| Cutting (hydraulic guide) | 1. Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start. 2.Material of blade: Cr12 mould steel with quenched treatment58-62℃ 3.Length : Automatic length measuring 4.Tolerance of length: 10+/- 1.5mm |

| PLC control system

| 1.Voltage, Frequency, Phase: 380V, 50 Hz, 3Phase 2.Automatic length measurement: 3.Automatic quantity measurement 4.Computer used to control length & quantity. Machine will automatically cut to length and stop when required quantity is achieved 5.Length inaccuracy can be amended easily 6.Control panel: Button-type switch and touch screen 7.Unit of length: millimeter (switched on the control panel) |

| Brand of Electric appliance | A: Screen, PLC, Inverter : Mitsubishi B: Encoders and other parts: Omron C:Hydraulic cylinder: Wuxi Wansheng D: Hydraulic valve: Yuken |

Shijiazhuang Yingyee Import&Export Co., Ltd.

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor from all the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

Roof roll forming machine

C and Z purlin roll forming machine

Downpipe roll forming machine

Hydraulic decoiler

Light keel roll forming machine6

Bending machine

Shearing machine

slitting machine

Roller shutter door roll forming machine

Training and Installation

1 We offer installation service local in paid, reasonable charge.

2 QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.