Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Roof sheet roll forming machines/Roof Sheet Forming Machine are widely used for building, include Corrugated Roof Sheet Roll Forming Machine,IBR Roof Sheet Roll Forming Machine, glazed tile roof sheet roll forming machine, Ridge Cap Tile Roll Forming Machine and Double Layer Roll Forming Machine.

These machines are high quality, save power heavy duty and low cost, which are easy to operate.

Specification:

Raw Material GI, PPGI, Aluminum coils Material thickness range 0.3-0.8mm Feeding width 1000mm, 1200mm, 1220mm, 1250mm Forming speed 25-30m/min(excluding cutting time) Rollers 18 rows Material of rollers 45# steel with chromed Shaft diameter and material 70mm, material is 40Cr Material of cutting blade Cr12 mould steel with quenched reatment Control system Mitsubishi/Siemens PLC control system with transducer inside Main motor power 3KW Hydraulic station power 3KW Voltage As your request

Ps:The above are for reference, we design machines according to your needs.

Working process:

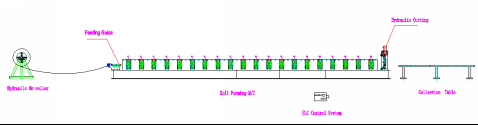

Decoiler- Feeding width- Roll forming machine- PLC control- Hydraulic cutting- Collecting platform

Pictures for machine:

Training and Installation :

1. We offer installation service local in paid, reasonable charge.

2. QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service:

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantages:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.