Common double layer roof sheet roll forming machine

$18000≥1Set/Sets

| Payment Type: | L/C,T/T,MoneyGram |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | TIANJIN |

$18000≥1Set/Sets

| Payment Type: | L/C,T/T,MoneyGram |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | TIANJIN |

Model No.: YY-001

Brand: YY

Applicable Industries: Building Material Shops, Construction Works

Showroom Location: None

Condition: New

Type: Tile Forming Machine, roof sheet roll forming machine

Tile Type: Colored Steel

Use: Roof

Production Capacity: 15-20m/min, 15m/min

Brand Name: YINGYEE

Dimension(L*W*H): 7000*1500*1500mm, 7000*1500*1500mm

Warranty: 1 Year

Key Selling Points: Easy To Operate

Rolling Thinckness: 0.3-0.8mm

Feeding Width: 1220mm

Machinery Test Report: Provided

Video Outgoing-inspection: Provided

Marketing Type: Ordinary Product

Warranty Of Core Components: 1 Year

Core Components: Plc

After-sales Service Provided: Engineers Available To Service Machinery Overseas

Power(W): 5.5kw

Thickness: 0.4-1mm

After Warranty Service: Online Support

Applicable Industry: Machinery Repair Shops, Home Use, Building Material Shops, Manufacturing Plant, Other

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Old And New: New

Machine Type: Tile Forming Machine

Productivity: 15 M/Min

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Energy Saving

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Place Of Origin: Hebei, China

Voltage: 380V 50Hz 3phases, 380 volts, 3 phase and 50 Hz or at buyer's request

Weight: 5000 kg

| Selling Units | : | Set/Sets |

| Package Type | : | BARE PACKING WITH WATERPROOF, ONE MACHINE NEEDS ONE 20FEET CONTAINER. |

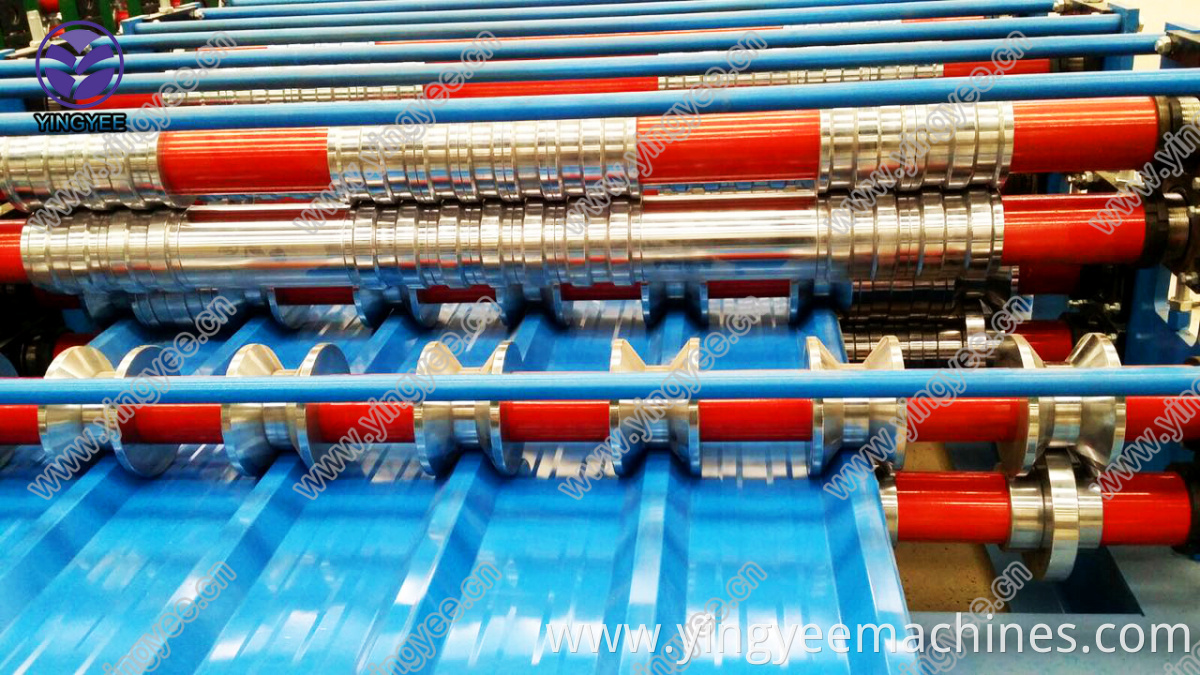

double layer rolling forming machine corrugated roofing trapezoidal/double layer roof sheet and glazed tiles roll former

Specification:

Our company is a manufacturer of roll forming machine. At present, our products have been exported to more than 70 countries and regions over the world, and maintained good cooperative relations with customer

| Performances | Parameters |

|

| Suitable Material | PPGI or galvanized coil | |

| Suitable material | Raw material width:1000 and 1250mm thickness 0.3-0.8mm | |

| Productivity | about 15m/min | |

| Roller forming steps | 17 step | |

| Roller material | 45# after heating treatment and with chromium | |

| Spacer, balance bar, screw | All do chromium to ensure beautiful appearance | |

| Diameter of active shaft | Φ70mm | |

| Main machine structure | 350H | |

| Wall plate | 16mm | |

| Power | 5.5KW main motor,cycloidal reducer work stable and no noise | |

| Shear | Hydraulic shear, blade material CR12 | |

| Transmission | 1’’ gear chain | |

| Control system | Delta PLC computer control system with Chrizi inverter to ensure precision; Winwen color touch screen. Program is made by English, working mode: automatic and manual | |

| Hydraulic system | 3kw hydraulic motor | |

| Voltage | AC380V/50HZ/3 phase or AC220-240V/60HZ/3 phase or AC220-240V/60HZ/single phase | |

| Upgrade manual Decoiler | Max loading weight:5000kgs,Inner Diameter:508-610mm,max coil width:1250mm | |

| Set off table | one pcs, 6 step roller, each is 3000mm long | |

| Size(length*width*height) | 7000*1500*1500MM | |

| Weight | 5000kgs | |

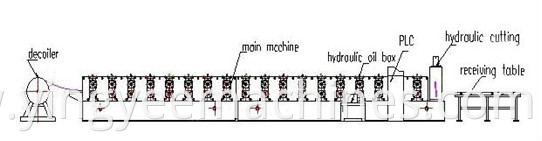

| Component | Upgrade manual decoiler-guide feeding-forming part-shear blade device--hydraulic system-PLC computer control cabinet-set off table | |

PS: the above are for reference; we design machines according to your needs.

Pictures:

Processing:

Shijiazhuang Yingyee Import&Export Co., Ltd.

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor from all the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

Roof roll forming machine

C and Z purlin roll forming machine

Downpipe roll forming machine

Hydraulic decoiler

Light keel roll forming machine6

Bending machine

Shearing machine

slitting machine

Roller shutter door roll forming machine

Training and Installation

1 We offer installation service local in paid, reasonable charge.

2 QT test is welcome and professional.

3. manual and using guide is optional if no visiting and no installation.

Certification and after service

1. Match the technology standard, ISO producing certification

2. CE certification

3. 12 months warranty since the delivery. Board.

Our advantage:

1. Short delivery period.

2. Effective communication

3. Interface customized.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.