Roof PU sandwich panel making machine

$65000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | TIANJIN XINGANG |

$65000≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | TIANJIN XINGANG |

Model No.: YY-001

Status: New

Applicable Industry: Advertising Company, Food &Amp; Beverage Shops, Food Shop, Building Material Shops, Other

Out-of-warranty Service: Video Technical Support, Field Maintenance And Repair Service, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Core Component Warranty Period: 1 Year

Place Of Origin: China

Warranty Period: 1 Year

Warranty: 1 Year

Application: Apartment

After-sale Service: Online Technical Support, Onsite Installation, Onsite Training, Onsite Inspection, Free Spare Parts, Return And Replacement, Other

Project Solution Capability: Graphic Design, 3d Model Design, Total Solution For Projects, Cross Categories Consolidation, Others

Place Of Origin: Hebei, China

Brand Name: YINGYEE

Model Number: YY--sandwich panel

Type: Plain Roof Tiles, Tile Forming Machine

Tile Type: Colored Steel

Production Capacity: 3-5m/min

Dimension(L*W*H): 34000x2500x1500MM

Voltage: 380V 50HZ 3phase 1 phase voltage 220V

Power(W): 18kw

Control System: PLC Control System with famous brand

Thickness: 0.3-0.8mm

Width: 1250mm

| Selling Units | : | Set/Sets |

| Package Type | : | As to the roll forming machine's package, it should be nude. But we'll protect the machine well before shipment, to prevent machines from rusting. Container: 2*40' forEPS Sandwich Panel production machinery |

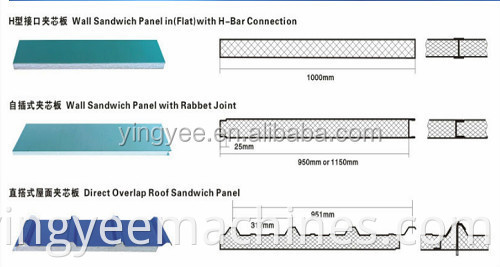

| Roof PU sandwich panel making machine is used to product all kinds of insulated sadnwich panel ,such as,wall panel ,roof panel ,cold room panel and garage door panel ,it is multifunctional . Besides ,it also is full automatic and continuous ,adpots PLC controlling system ,only need 6 workers to operate ,could help boss save alot o labor . It is consisted of the following equipments :Decoiler ,roll forming machine ,heating machine ,PU foaming machine ,double belt laminating machine ,automatic cutter .The panel cooling machine ,automatic stacker and packing machine are optional . Moreover,both the decoiler, roll forming machine, the laminating system and cutter can work independently. | ||||||||||||||||||

| Features: | ||||||||||||||||||

| 1.Beautiful appearance, low noise, high efficiency 6.The roller matrial is medium carbon alloy steel ,with high quality . 7.The length of double belt laminating machine could be made according to customers needs . | ||||||||||||||||||

| Main Techincal specification: | ||||||||||||||||||

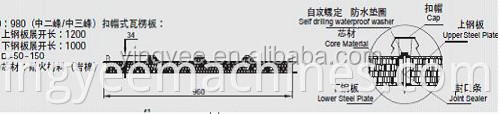

| 1.Decoiler Bearing :5T / 7.5T / 10T Speed of uncoiling :0--12m/min(adjustable) Inner diameter of coiler : Ø508 , Ø610mm Outer diameter of coil:≤1200mm 2.Roll forming machine

3. Heating machine Way of heating :gas or electricity 4.Double belt laminating machine Total length :18--36m Moving speed:0--12m/mim 5. Auto tracking cutter Horizontal moving length: 6m |

Shijiazhuang Yingyee Import&Export Co., Ltd.

YINGYEE is the manufacturer specialized in various cold forming machineries and automatic production lines. We have a wonderful team with highly technology and excellent sales, which offer professional products and related service. We paid attention to quantity and after service, got great feedback and honor from all the clients. We have a great team for after service. We have sent several patch after service team to oversea to finish the products installation and adjustment.

Our products were sold to more than 20 countries already. Also included US and Germany.

Main product :

Roof roll forming machine

C and Z purlin roll forming machine

Downpipe roll forming machine

Hydraulic decoiler

Light keel roll forming machine6

Bending machine

Shearing machine

slitting machine

Roller shutter door roll forming machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.